World class innovation.

Thomas Conveyor Company has been in the business of designing and manufacturing complete conveyor systems for over 60 years. We believe in customer service like no other, and we're committed to providing you with the highest quality conveyor systems.

From concept to completion, our team of experts is here to help you every step of the way. We know how important it is to get your project done on time and without fail and we promise to do everything in our power to make sure that happens.

Annual

Reduced Downtime

Annual Documented

Savings Per User

Average Days To Ship

Anywhere In North America

Mining, Aggregate

and Cement

Forest and Paper

Food and Beverage

Annual

Reduced Downtime

Annual Documented

Savings Per User

Average Days To Ship

Anywhere In North America

Mining, Aggregate

and Cement

Forest and Paper

Food and Beverage

General Bucket Elevator Options & Features

Learn more about general bucket elevator options and features including platforms, split sprockets, take-ups, belt splicing kits and more.

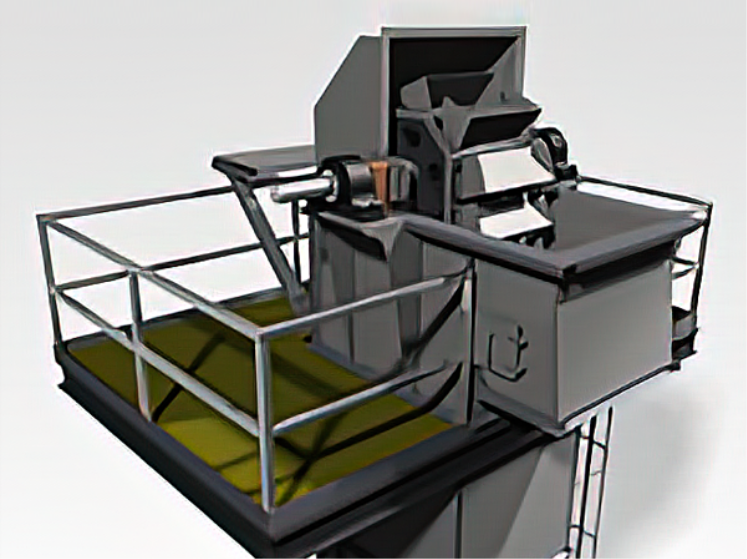

Super Capacity Elevators

Super capacity elevators are continuous style elevators that are designed to move larger capacities compared to our standard continuous model. Along with the increased rate these elevators are made with heavy duty components including the buckets, chain, bearings, & housing.

Let's Work Together.

Thomas Conveyor Company is dedicated to helping our clients maximize their operations and reduce costs. Together, we can leverage our exclusive technologies, expertise, and capabilities to help you do just that.

Let's get started.

Your Conveyor Screw Quote has been submitted.

I would like to